Overview

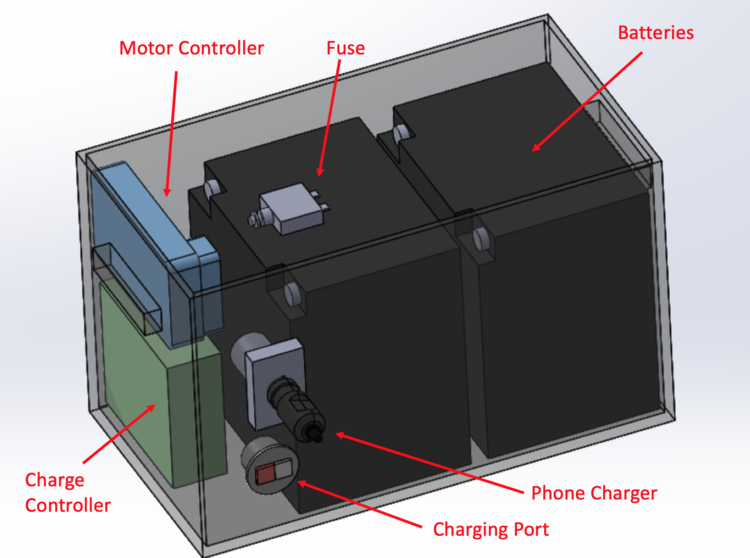

The electric wagon was designed by EWB-SCU to carry clay for our community from its source at the bottom of a valley to the site of processing at the top of the hill. It empowers our community members by saving them time and energy, allowing them to spend more time with their families and their business. The team used a garden cart for the frame and designed custom brackets to attach a motor and wheels. Additionally, a motor and charge controller were included with two batteries inside the cart allowing the system to be easily driven and charged using a 300W solar panel. The system was also able to charge the community member’s phones, preventing them from having to walk to town and pay for a charge. While in Rwanda, we spent a week teaching them how to use and maintain the wagon. The cart has allowed the community to increase their tile output.

Background: Carrying Clay

Our partner cooperative gathers clay at the bottom of a valley, carrying it on their heads up a steep hill before mixing, pressing, and firing the clay into roof tiles. The pathway to and from this valley was a rough dirt trail approximately one mile in length and three feet wide. While this trail width was acceptable for foot traffic, the path would need to be widened for any clay transportation system to be used properly, safely, and effectively.

During Summer 2017, the cooperative brought the team to a neighboring business that used tractors to haul clay for them, expressing their desire to have a similar machine for their own needs. The tractors were too wide for the cooperative’s trail, difficult to control, and overpowered compared to the community’s needs. It was also important that the wagon was electric because gasoline is costly and difficult for the community to acquire.

Design: Motorized Wagon

EWB-SCU began the electric wagon design after need finding and data gathering during Summer 2017. Elevation data collected showed that the clay needed to be transported 250 feet of elevation over a ⅓ mile distance with an average slope of 8° degrees. The worst parts of the trail are as steep as 20° with occasional sharp turns and uneven terrain. Members of the cooperative make this journey carrying 15 lb at a time. About 15 cubic feet or roughly 1250 lb of wet clay needed to carried each week.

EWB-SCU decided to purchase a garden wagon as a base frame for the cart instead of welding a custom frame as it was more cost-effective and would expedite the design process allowing the team to focus on the critical electrical and mechanical systems. A Sandusky Lee CW3418 Steel utility wagon was chosen as a base frame for the electric wagon because it satisfied the 2 ft width requirement of the trail and could hold 400 lb. As community members cannot easily lift much more than 100 lb, the 40 lb frame would allow the cart to be more easily lifted if it were to get stuck.

After considering the various battery types, Deep Cycle AGM Lead Acid batteries were the most practical to use because of their high performance and ability to be sourced in Rwanda. Two batteries are required in series to make 24V for the transaxle. The capacity of the battery was chosen to be 22 Ah based off of the power input required to run the transaxle at full 400W power for 75 minutes without depleting the batteries to lower than 50%. If each haul was 250 lb, the community could transport all of their clay in five 15 minute trips. This is a conservative estimate and EWB-SCU expects the cart to run longer because the cart will not draw full power the entire trip, especially on the way down.

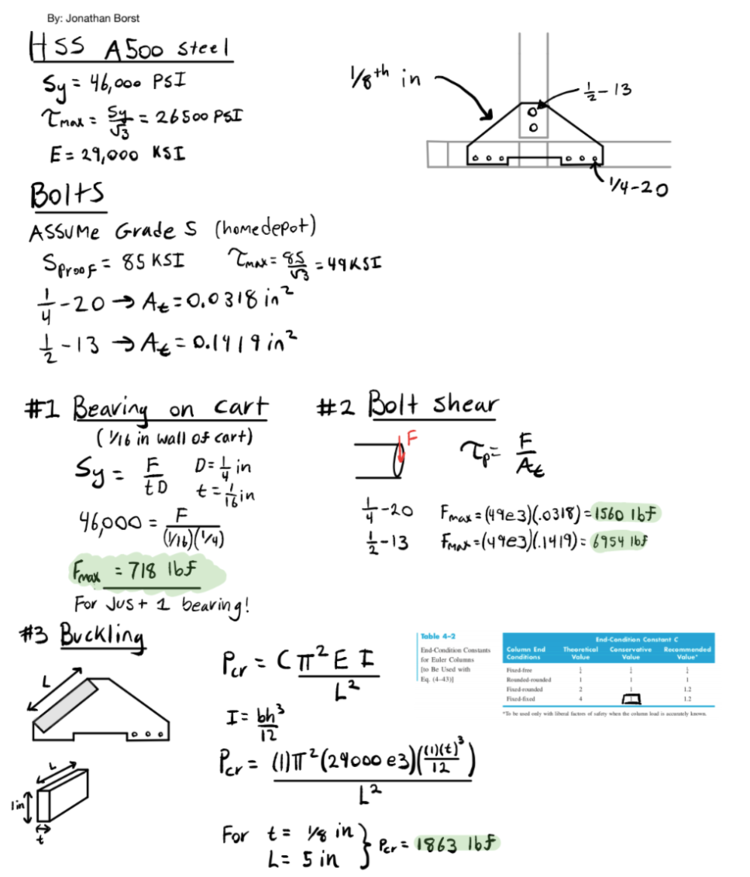

The most calculations went into ensuring the structural integrity of the cart and the modifications required to add wheels. Once the components were chosen, further cart design was done using Computer Aided Design (CAD) on Solidworks calculations for the strengths of brackets were done by hand.

Implementation: Driving and Maintenance